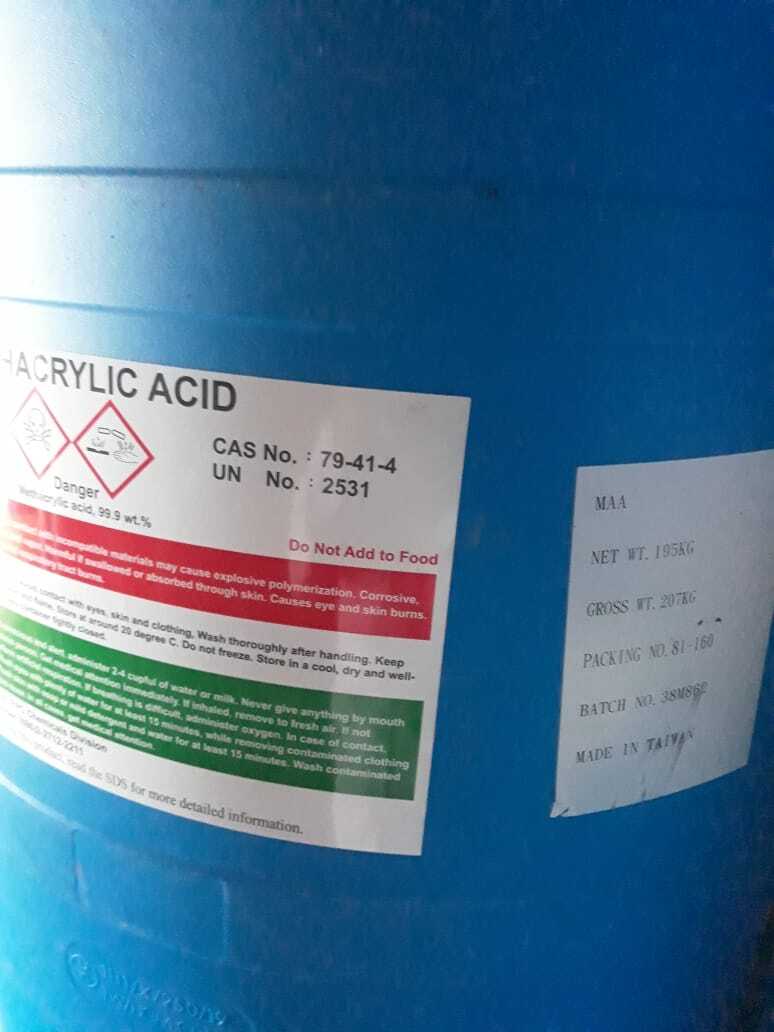

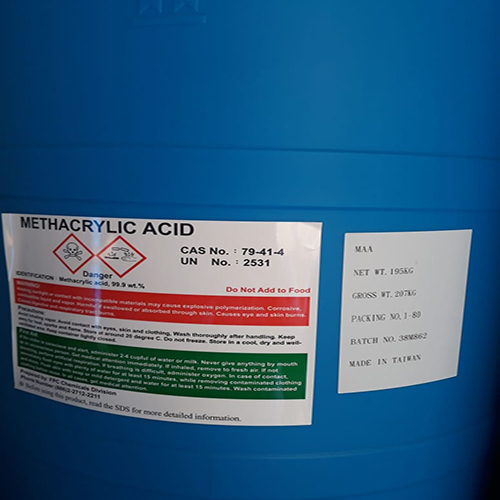

मà¥à¤¥à¥à¤à¥à¤°à¥à¤²à¤¿à¤ à¤à¤¸à¤¿à¤¡ (MAA)

मà¥à¤¥à¥à¤à¥à¤°à¥à¤²à¤¿à¤ à¤à¤¸à¤¿à¤¡ (MAA) Specification

- एच एस कोड

- 2916131000

- ग्रेड

- औद्योगिक

- आण्विक सूत्र

- C4H6O2

- प्रॉपर्टीज़

- मा, एक कार्बनिक यौगिक है।

- उपयोग

- कोटिंग्स

- ईआईएनईसीएस नं

- 201-204-4

- घनत्व

- 1.02 ग्राम/सीएमए ग्राम प्रति घन सेंटीमीटर (g/cm3)

- दिखावट

- स्पष्ट, रंगहीन

- मेल्टिंग पॉइंट

- 15 ए ए सी

- कैस नं

- 79-41-4

- आणविक भार

- 86.06 ग्राम/मोल ग्राम (g)

- भौतिक रूप

- लिक्विड

मà¥à¤¥à¥à¤à¥à¤°à¥à¤²à¤¿à¤ à¤à¤¸à¤¿à¤¡ (MAA) Trade Information

- Minimum Order Quantity

- 200 Kilograms

- आपूर्ति की क्षमता

- 20000 प्रति सप्ताह

- डिलीवरी का समय

- दिन

- पैकेजिंग का विवरण

- 200 किलो

About मà¥à¤¥à¥à¤à¥à¤°à¥à¤²à¤¿à¤ à¤à¤¸à¤¿à¤¡ (MAA)

Product Overview:

Methacrylic Acid (MAA) is a highly reactive monomer used in the production of specialty polymers, coatings, adhesives, and resins. This colorless, corrosive liquid features a carboxyl functional group, making it an essential component for enhancing adhesion, chemical resistance, and crosslinking in polymer formulations. MAA is widely used in applications requiring strong bonding, weather resistance, and durability.

Key Features & Benefits:

Strong Adhesion Properties Improves bonding strength in coatings and adhesives.

High Chemical & Weather Resistance Enhances durability in harsh conditions.

Excellent Crosslinking Ability Increases mechanical strength in polymer systems.

Versatile Compatibility Copolymerizes with acrylates, methacrylates, and styrenics.

Water-Soluble & Hydrophilic Ideal for waterborne coatings and dispersions.

Applications:

Acrylic Resins & Emulsions: Used in coatings, inks, and surface treatments.

Adhesives & Sealants: Enhances bonding performance and chemical stability.

Waterborne & Solvent-Based Coatings: Provides superior durability and flexibility.

Textile & Leather Finishes: Improves fabric treatment and water resistance.

Superabsorbent Polymers (SAP): Key ingredient in hygiene products and gels.

Get in Touch Today!

एक उद्धरण का अनुरोध करें | Order a Sample | Speak to Our Experts

Key Chemical Properties

Methacrylic acid is an organic compound formulated as C4H6O2. This clear, colorless liquid possesses a melting point of 15C and a density of 1.02 g/cm. Recognized for its acrid odor, it features carboxylic acid functionality, making it reactive for various industrial processes. Its versatile chemical structure enables its use as a critical intermediate in polymer production and specialty chemicals.

Diverse Industrial Applications

MAA acts as a vital building block for many products, including paints, coatings, adhesives, and leather treatments. It is highly sought after in the manufacture of plastics, film-forming agents, thickeners, lubricants, and materials used in medical and textile sectors. Its primary role is to enhance product properties such as flexibility, adhesion, and durability.

FAQs of METHACRYLIC ACID (MAA):

Q: How is methacrylic acid (MAA) typically used in industrial applications?

A: Methacrylic acid is primarily used in the manufacture of coatings, adhesives, plastics, and ion-exchange resins. It serves as a raw material or intermediate for products that require improved flexibility, bond strength, or durability, such as paints, varnishes, sealants, and leather finishing agents.Q: What are the main benefits of using methacrylic acid in coatings and adhesives?

A: MAA imparts excellent adhesion, weather resistance, and flexibility to coatings and adhesives. These properties are essential for enhancing the durability and performance of finished products, making them suitable for demanding industrial and commercial uses.Q: When should methacrylic acid be used over other carboxylic acids?

A: Methacrylic acid is preferred when specific performance characteristicssuch as rapid polymerization, high reactivity, and strong bonding capacityare required, especially in the production of acrylic polymers and specialty resins.Q: Where is methacrylic acid commonly manufactured and supplied?

A: MAA is produced and distributed worldwide, with notable manufacturers and suppliers, including those based in Korea North. It can be sourced through chemical distributors, exporters, and direct from manufacturers for industrial purposes.Q: What safety precautions should be taken when handling methacrylic acid?

A: Due to its acrid odor and corrosive nature, appropriate protective gear such as gloves and goggles should be worn. Proper ventilation and adherence to safety guidelines ensure safe handling, storage, and transportation.Q: How does methacrylic acid contribute to plastic and medical material production?

A: In the plastics and medical material sectors, MAA is used as a monomer or modifier to enhance product transparency, flexibility, and biocompatibility. It improves the quality and function of specialized materials like contact lenses and medical devices.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in मोनोमर Category

डाइमिथाइल एमिनोइथाइल मेथैक्रिलेट (DMAEMA)

न्यूनतम आदेश मात्रा : 200

माप की इकाई : किलोग्राम/किलोग्राम

भौतिक रूप : लिक्विड

मूल्य की इकाई : Kilograms/Kilograms

ग्रेड : औद्योगिक

एप्लीकेशन : इंडस्ट्रियल

मिथाइल मेथाक्रिलेट (एमएमए)

न्यूनतम आदेश मात्रा : 200

माप की इकाई : किलोग्राम/किलोग्राम

भौतिक रूप : लिक्विड

मूल्य की इकाई : Kilograms/Kilograms

ग्रेड : औद्योगिक

एप्लीकेशन : इंडस्ट्रियल

ब्यूटाइल एक्रिलेट (बैम)

न्यूनतम आदेश मात्रा : 200

माप की इकाई : किलोग्राम/किलोग्राम

भौतिक रूप : लिक्विड

मूल्य की इकाई : Kilograms/Kilograms

ग्रेड : औद्योगिक

एप्लीकेशन : इंडस्ट्रियल

2 हाइड्रोक्सी एथिल एक्रिलेट

न्यूनतम आदेश मात्रा : 200

माप की इकाई : किलोग्राम/किलोग्राम

भौतिक रूप : लिक्विड

मूल्य की इकाई : Kilograms/Kilograms

ग्रेड : औद्योगिक

एप्लीकेशन : इंडस्ट्रियल

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें