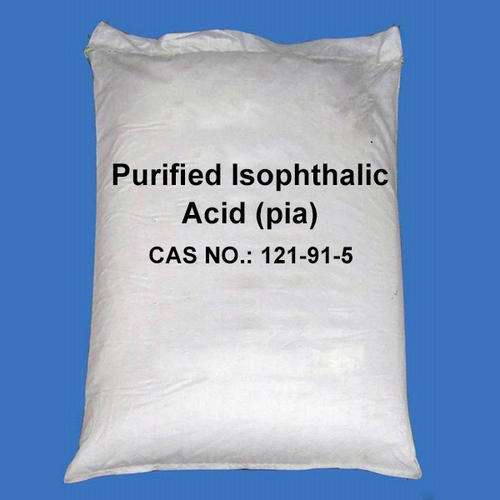

à¤à¤à¤¸à¥à¤«à¥à¤²à¤¿à¤ à¤à¤¸à¤¿à¤¡

MOQ : 200 Kilograms

à¤à¤à¤¸à¥à¤«à¥à¤²à¤¿à¤ à¤à¤¸à¤¿à¤¡ Specification

- कैस नं

- 121-91-5

- भौतिक रूप

- गंध

- आणविक भार

- 166.14 ग्राम/मोल ग्राम (g)

- ईआईएनईसीएस नं

- 204-506-4

- विषैला

- स्टोरेज

- ग्रेड

- औद्योगिक

- घनत्व

- 1.53 ग्राम/सीएमए ग्राम प्रति घन सेंटीमीटर (g/cm3)

- उपयोग

- हाइड्रोथर्मल और सोनोकैमिकल प्रक्रिया द्वारा धातु समन्वय पॉलिमर।

- आण्विक सूत्र

- C8H6O4

- दिखावट

- White crystalline powder

- एप्लीकेशन

- मेल्टिंग पॉइंट

- 341-343 ए सी (लिट।)

- प्रॉपर्टीज़

- आइसोफथालिक एसिड रंगहीन ठोस होता है जो कि फथालिक एसिड और टेरेफ्थेलिक एसिड का एक आइसोमर होता है।

- सामग्रियां

- Isophthalic Acid (C H O )

à¤à¤à¤¸à¥à¤«à¥à¤²à¤¿à¤ à¤à¤¸à¤¿à¤¡ Trade Information

- Minimum Order Quantity

- 200 Kilograms

- आपूर्ति की क्षमता

- 2000 प्रति महीने

- डिलीवरी का समय

- दिन

- पैकेजिंग का विवरण

- 25 किलोग्राम का बैग

About à¤à¤à¤¸à¥à¤«à¥à¤²à¤¿à¤ à¤à¤¸à¤¿à¤¡

A high-purity dicarboxylic acid widely used in PET resins, alkyd coatings, and high-performance polymers. It improves chemical resistance, mechanical strength, and thermal stability in applications like fiberglass-reinforced plastics, powder coatings, and adhesives.Versatile Industrial Applications

Isophthalic Acid is primarily used in the creation of metal coordination polymers, benefiting diverse industrial processes. Its role as a precursor in the fabrication of nanocomposites, including isophthalic acid-zirconium(IV), enables the production of crystalline tetragonal zirconia (ZrO2). These materials are crucial in sectors like advanced ceramics and catalysis.

Distinct Physical Properties

This compound appears as a white crystalline powder, with a notable melting point of 341-343C and density of 1.53 g/cm3. Its molecular structure (C8H6O4) is distinguished from its isomers, phthalic and terephthalic acid, ensuring it meets specific industrial requirements. The product is recognized for its stability and safety, as it is non-poisonous.

FAQs of ISOPHTHALIC ACID:

Q: What are the main uses of Isophthalic Acid in industry?

A: Isophthalic Acid is primarily used in the synthesis of metal coordination polymers and as a precursor in forming isophthalic acid-zirconium(IV) nanocomposites. These nanocomposites are further processed to produce crystalline tetragonal ZrO2, essential in ceramics and catalysis.Q: How is Isophthalic Acid typically processed for advanced materials?

A: Isophthalic Acid undergoes hydrothermal and sonochemical methods to create metal coordination polymers. When combined with zirconium(IV), it forms nanocomposites that are thermally decomposed to yield crystalline tetragonal ZrO2.Q: What benefits does Isophthalic Acid offer compared to its isomers?

A: Compared to its isomers, phthalic and terephthalic acid, Isophthalic Acid has unique reactivity and stability, making it especially suitable for producing specialty polymers and advanced ceramic materials.Q: Where can Isophthalic Acid be sourced within India?

A: Isophthalic Acid is readily available from numerous distributors, exporters, importers, manufacturers, and suppliers throughout India, catering to the countrys industrial and research needs.Q: What are the safety considerations when handling Isophthalic Acid?

A: Isophthalic Acid is classified as non-poisonous. However, standard industrial safety protocols, such as using protective equipment and ensuring proper ventilation, should always be observed when handling the powdered material.Q: When should Isophthalic Acid be chosen for polymer production?

A: Select Isophthalic Acid for polymer applications when specific thermal stability, crystallinity, or compatibility properties are required, particularly for high-performance materials or nanocomposite precursors.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in अन्य Category

पेंटाएरिथ्रिटोल 98%

न्यूनतम आदेश मात्रा : 200

माप की इकाई : किलोग्राम/किलोग्राम

ग्रेड : औद्योगिक

भौतिक रूप : Powder

प्रॉपर्टीज़ : Pentaerythritol विभिन्न डेंड्रिमर्स और स्टार के आकार के पॉलिमर को संश्लेषित करने के लिए एक बहुमुखी शुरुआती सामग्री है।

ईआईएनईसीएस नं : 2041049

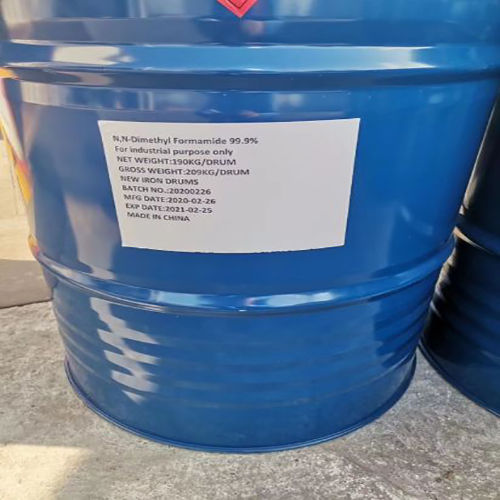

डाइमिथाइल फॉर्मामाइड (DMF)

न्यूनतम आदेश मात्रा : 200

माप की इकाई : किलोग्राम/किलोग्राम

ग्रेड : औद्योगिक

भौतिक रूप : लिक्विड

प्रॉपर्टीज़ : DMF पौधे के ऊतकों से क्लोरोफिल के अलगाव के लिए नियोजित एक उपयोगी विलायक है।

ईआईएनईसीएस नं : 2006795

नोनील फिनोल

न्यूनतम आदेश मात्रा : 200

माप की इकाई : किलोग्राम/किलोग्राम

ग्रेड : औद्योगिक

भौतिक रूप : लिक्विड

ईआईएनईसीएस नं : 2843255

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें