POLYETHERAMINE (PEA)

POLYETHERAMINE (PEA) Specification

- Storage

- Dry Place

- Density

- 1.035 g/mL Gram per millilitre (g/mL)

- Form

- Liquid

- Molecular Weight

- 90.1243 Grams (g)

- Chemical Name

- POLY ETHER AMINE

- CAS No

- 65605-36-9

- Grade

- Industrial Grade

- Usage

- Epoxy curing agent Reacts with carboxylic acids to form hot melt adhesives Reacts quickly with isocyanates Salts may be formed readily for surfactant use

POLYETHERAMINE (PEA) Trade Information

- Minimum Order Quantity

- 200 Kilograms

- Supply Ability

- 20000 Kilograms Per Week

- Delivery Time

- 7 Days

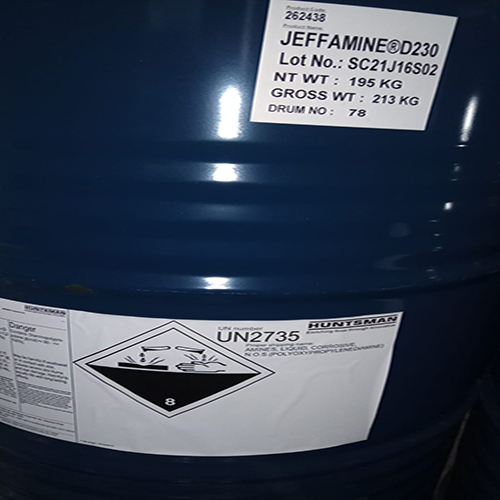

- Packaging Details

- 195 KG MS DRUM

About POLYETHERAMINE (PEA)

Polyetheramine (PEA) is a versatile amine-based compound containing repeating ether groups, offering excellent flexibility, low viscosity, and superior chemical reactivity. It is widely used in coatings, adhesives, composites, and fuel additives due to its exceptional compatibility with epoxy resins and polyurethane systems.

Key Applications:

Epoxy Curing Agents Enhances adhesion, toughness, and chemical resistance in coatings, adhesives, and composites.

Polyurethane Systems Functions as a chain extender and hardener in elastomers and foams.

Fuel & Lubricant Additives Improves engine performance by reducing deposits and enhancing combustion.

Water Treatment & Corrosion Inhibitors Helps prevent scaling and corrosion in industrial applications.

Surfactants & Dispersants Used in specialty chemical formulations for emulsification and wetting properties.

Composites & Advanced Materials Provides improved impact resistance and flexibility in fiber-reinforced materials.

Features & Benefits:

High reactivity and excellent compatibility with epoxy resins

Improves toughness, flexibility, and chemical resistance in coatings and composites

Enhances fuel efficiency and engine performance in additive applications

Low viscosity for easy processing and formulation versatility

Available in various grades and packaging sizes to suit industrial needs. Contact us today for specifications, safety data, and pricing!

Key Features of Polyetheramine (PEA)

Polyetheramine (PEA) is recognized for its fast reactivity with isocyanates and carboxylic acids. Its liquid form and moderate density allow for easy handling and mixing in industrial processes. It is most commonly used as a curing agent for epoxy systems, contributing to durable and robust end products.

Applications and Uses

PEAs primary usage lies in epoxy curing, providing enhanced strength and flexibility to cured materials. Additionally, its chemical properties make it suitable for producing hot melt adhesives when reacted with carboxylic acids and for surfactant formation through salt generation, expanding its functionality in modern manufacturing.

FAQs of POLYETHERAMINE (PEA):

Q: How should Polyetheramine (PEA) be stored to maintain its effectiveness?

A: Polyetheramine should be stored in a dry place to prevent moisture absorption and maintain its chemical integrity, ensuring optimal performance in industrial applications.Q: What are the main industrial applications of Polyetheramine (PEA)?

A: Polyetheramine is used chiefly as an epoxy curing agent, in the production of hot melt adhesives (by reacting with carboxylic acids), and for creating surfactants through salt formation. Its versatility supports various manufacturing needs.Q: When is Polyetheramine typically used in manufacturing processes?

A: PEA is typically used during the curing phase of epoxy resin production, in adhesive formulation, and in surfactant production, whenever rapid reaction and enhanced material properties are required.Q: Where can Polyetheramine (PEA) be sourced in India?

A: Polyetheramine is accessible through reputable distributors, exporters, importers, manufacturers, and suppliers throughout India, providing reliable supply for industrial operations.Q: How does Polyetheramine benefit hot melt adhesive formulation?

A: When reacted with carboxylic acids, Polyetheramine facilitates the production of hot melt adhesives, offering strong bonding properties and swift application capabilities in manufacturing settings.Q: What is the process for using Polyetheramine as an epoxy curing agent?

A: To use Polyetheramine as an epoxy curing agent, it is blended with epoxy resins. Its rapid reactivity initiates cross-linking, resulting in tough, high-performance coatings and composite materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Amines Category

MONOETHANOLAMINE (MEA)

Minimum Order Quantity : 200 Kilograms

Grade : Industrial Grade

Usage : Cleaning industry ,Corrosion Inhibitors, Pharmaceuticals, Textile Auxiliaries, Cosmetics and Wood Chemicals, Cement Grinding Aids

Form : Liquid

CAS No : 141435

Molecular Weight : 61.1 Grams (g)

AMINOETHYLPIPERAZINE (AEP)

Minimum Order Quantity : 200 Kilograms

Grade : Industrial Grade

Usage : Asphalt additives Mineral processing aids Corrosion inhibitors Epoxy curing agents Polyamide resins Urethane chemicals

Form : Liquid

CAS No : 140318

Molecular Weight : 129.20 g/mol Grams (g)

PRIMENE 81R AMINE

Minimum Order Quantity : 200 Kilograms

Grade : Industrial Grade

Usage : Lubricants,Fuel additives, Industrial surfactants,Solventbased dyes, Oilbased metalworking fluids,Oilfield and refinery chemicals, Chemical intermediate for manufacture of other compounds,

Form : Liquid

CAS No : 68955533

Molecular Weight : 171.32 Kilograms (kg)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry