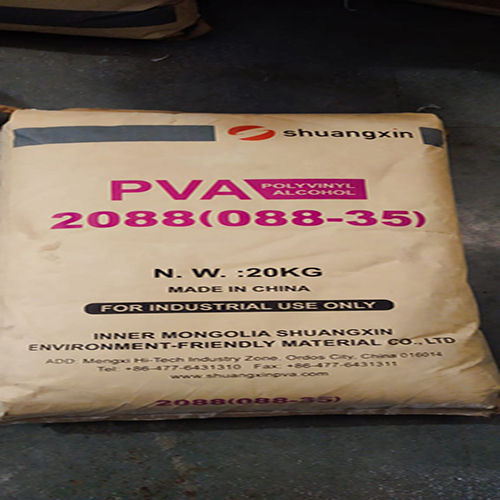

POLYVINYL ALCOHOL (PVA)

POLYVINYL ALCOHOL (PVA) Specification

- Grade

- Industrial

- CAS No

- 9002-89-5

- Molecular Formula

- (C2H4O)x

- Poisonous

- NO

- Physical Form

- Powder

- Usage

- PVA used in reducing removal in the process of sizing and weaving to maintain factory cleaning; as fiber reinforcement in concrete; as an agent in medical procedures; used in eye drops and hard solution as a lubricant; mainly used as adhesive, in printing industry and textile industry.

- Appearance

- White to off-white powder or granules

- Melting Point

- 200 C

- Storage

- Room Temperature

- Density

- 1.19 g/cm

- Ingredients

- Polyvinyl Alcohol (C H O)

- Properties

- Water-soluble, film-forming, adhesive, high tensile strength, good chemical resistance

POLYVINYL ALCOHOL (PVA) Trade Information

- Minimum Order Quantity

- 200 Kilograms

- Supply Ability

- 2000 Kilograms Per Month

- Delivery Time

- 7 Days

- Packaging Details

- 20KG BAG

About POLYVINYL ALCOHOL (PVA)

Polyvinyl alcohol (PVA) is a non-polluting water-soluble polymer, usually white or slight yellow floccule, flake, granular or powder solid. Its performance is between plastic and rubber. It has good adhesion, film-forming ability, insulation, oil resistance, abrasion resistance and gas barrier property, etc.Versatile Applications Across Industries

Polyvinyl Alcohols flexible characteristics make it essential in a range of fields. It serves as a key adhesive in textile and printing industries, enhances concrete durability through fiber reinforcement, and functions as a lubricant in medical products like eye drops. Its adaptability stems from its water solubility, film-forming ability, and chemical resistance.

Stable and Safe Composition

Composed of polyvinyl alcohol [(C2H4O)x], PVA is non-poisonous and safe for industrial use. Its physical form as a powder or granule ensures easy handling and consistent application, while its impressive melting point and density uphold its structural properties under various conditions.

FAQs of POLYVINYL ALCOHOL (PVA):

Q: How is Polyvinyl Alcohol (PVA) typically used in industrial applications?

A: PVA is used as an adhesive in the printing and textile industries, as fiber reinforcement in concrete, for reducing residue during fabric sizing and weaving, and as a lubricant in medical products such as eye drops. Its versatility arises from its water-solubility, adhesive properties, and tensile strength.Q: What benefits does PVA provide when incorporated into concrete?

A: When used as a fiber reinforcement in concrete, PVA improves the materials tensile strength and durability, reducing the formation of microcracks and enhancing the long-term structural integrity of construction projects.Q: Where should Polyvinyl Alcohol powder be stored for maximum shelf life?

A: PVA powder should be stored at room temperature in a dry, sealed container, away from direct moisture and humidity, to ensure its stability and maintain its physical and chemical properties.Q: What is the process for dissolving PVA in water for industrial use?

A: To dissolve PVA powder, gradually add it to warm water while continuously stirring. The waters temperature should typically be between 80C and 90C to allow for efficient dissolution and to form a clear, homogeneous solution for use as an adhesive or binder.Q: Is Polyvinyl Alcohol (PVA) safe to handle and use?

A: Yes, PVA is classified as non-poisonous and safe for standard industrial applications. However, it is recommended to use personal protective equipment such as gloves and masks when handling the powder to prevent inhalation or skin irritation.Q: What are some specific benefits of using PVA as a film-forming and adhesive agent?

A: PVAs strong film-forming and adhesive qualities provide reliable bonding in materials, making it especially valued in the printing and textile industries. It ensures clean application, easy residue removal, and durable adhesion.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Others Category

TETRAHYDROFURAN (THF)

Minimum Order Quantity : 200 Kilograms

Properties : Low viscosity, highly volatile, excellent solvency, miscible with water and organic solvents

Physical Form : Liquid

Grade : Industrial

Ingredients : Tetrahydrofuran (C H O)

Density : 1.05 g/cm

PENTAERYTHRITOL 98%

Minimum Order Quantity : 200 Kilograms

Properties : High thermal stability, low volatility, watersoluble, nonhygroscopic

Physical Form : Powder

Grade : Industrial / Technical

Ingredients : Pentaerythritol (C H O )

Density : 944 kg/m Kilogram per cubic meter (kg/m3)

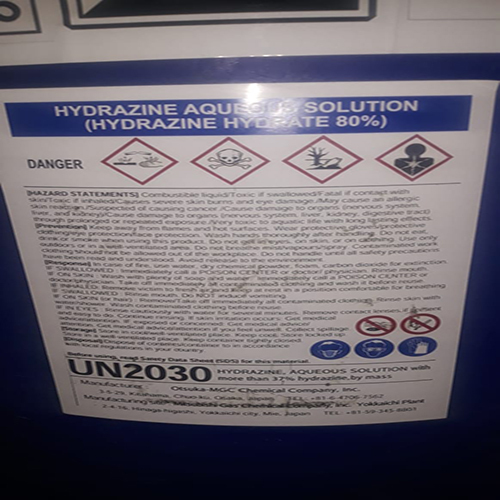

HYDRAZINE HYDRATE

Minimum Order Quantity : 200 Kilograms

Properties : It can be used as polymerization catalysts, food additives, soldering fluxes and in manufacture of surfactants, detergents and plasticizer.

Physical Form : Liquid

Grade : Industrial

Ingredients : Hydrazine (N H ) with water

Density : 1 g/cm Gram per cubic centimeter(g/cm3)

BISPHENOL A (BPA)

Minimum Order Quantity : 200 Kilograms

Properties : Bisphenol A is a colourless solid which is soluble in most common organic solvents, but has very poor solubility in water.

Physical Form : Powder

Grade : Industrial

Density : 1.217 g/cm3 Gram per cubic centimeter(g/cm3)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry